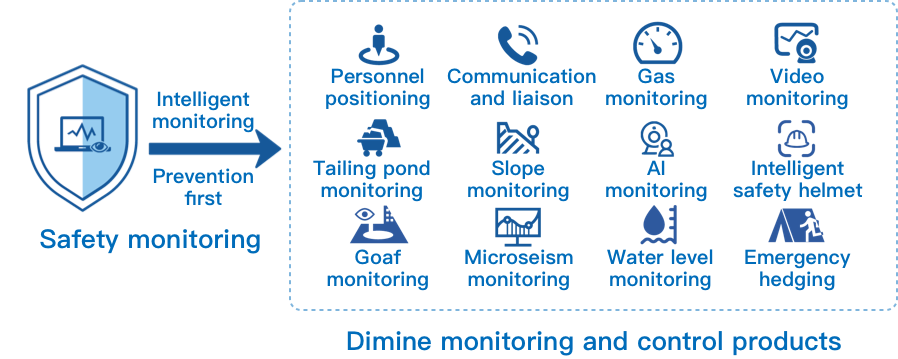

In the face of potential safety hazards such as underground gas, dust, roof fall and rib spalling, explosion and burning, seepage and open-pit mine slope stability and in conjunction with relevant national safety provisions, Dimine, after many years of practice, provides mining enterprises with a series of intelligent monitoring products such as six underground safety systems, microseism online monitoring, tailing pond online monitoring, slope online monitoring, personnel safety management and AI monitoring.

1、Six safety systems⸺Real-time online monitoring

The six mine safety systems are an integrated system that adopts standard industrial Ethernet ring network structure, mining intrinsically safe three-in-one base station and 3D VR management and control platform and integrates personnel and equipment positioning, personnel attendance, environment monitoring, video monitoring, dispatching communication, wireless communication and IP broadcast. It can realize surface and underground voice communication, tracking and positioning of personnel and equipment, remote monitoring of underground critical equipment (such as fan, pump, etc.), image and video monitoring of underground critical locations, and monitoring and control of various environmental parameters (such as CO, NO2, etc.).

2、Microseism online monitoring⸺Full time domain intelligent monitoring

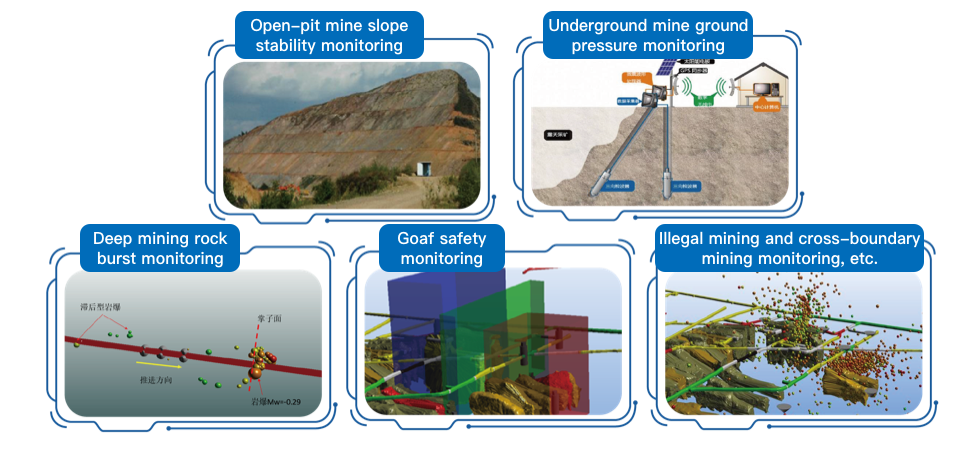

The system uses a sensor to monitor the weak seismic wave arising from the mine rock mass deformation and fracture failure process. By applying the seismological principle to analyze the fluctuation information, the system judges and evaluates the stability of the monitoring object, thus providing basis to mine disaster forecast and control.

3、Personnel safety management system ⸺Safety supervision intelligent device

The system carries out stope personnel safety management based on GPS positioning. On the basis of safety helmet, the intelligent integrated safety helmet integrates such modules as camera, voice and communication mainboard, and has such functions as HD video acquisition, voice communication, intercom and local video storage. While realizing data acquisition and real-time communication, this wearable device genuinely frees the hands of field operation personnel, and is applicable to such operation scenarios as open-pit mine (metal mine, building material mine, coal mine, etc.).

4、Slope online monitoring

DM SMS slope online monitoring system employs wireless intelligent sensing technology, IoT technology, cloud computing technology, embedded technology, communication and multimedia information technology, and complies with relevant national standards. The system can monitor the slope displacement, stress, underground water, blasting vibration and rainfall of open-pit mines, predict the possibility of slope instability and the danger of landslide, provides technical basis for preventing landslide and possible slide and creep deformation, and predict and forecast the development trend of slope displacement and deformation.

5、Tailing pond online monitoring

The tailing pond online monitoring system is a system that utilizes IoT, sensor, signal transmission, 3D virtual simulation and other technologies to conduct online monitoring of tailing pond dam surface displacement, internal displacement, dry beach length, water level, phreatic line, rainfall and video in accordance with relevant national standards. Relying on 3D virtual reality software, the system establishes a 3D analysis and early warning model to carry out online monitoring and forecast of the safety status of the tailing pond, thus effectively preventing and containing the occurrence of major accidents.