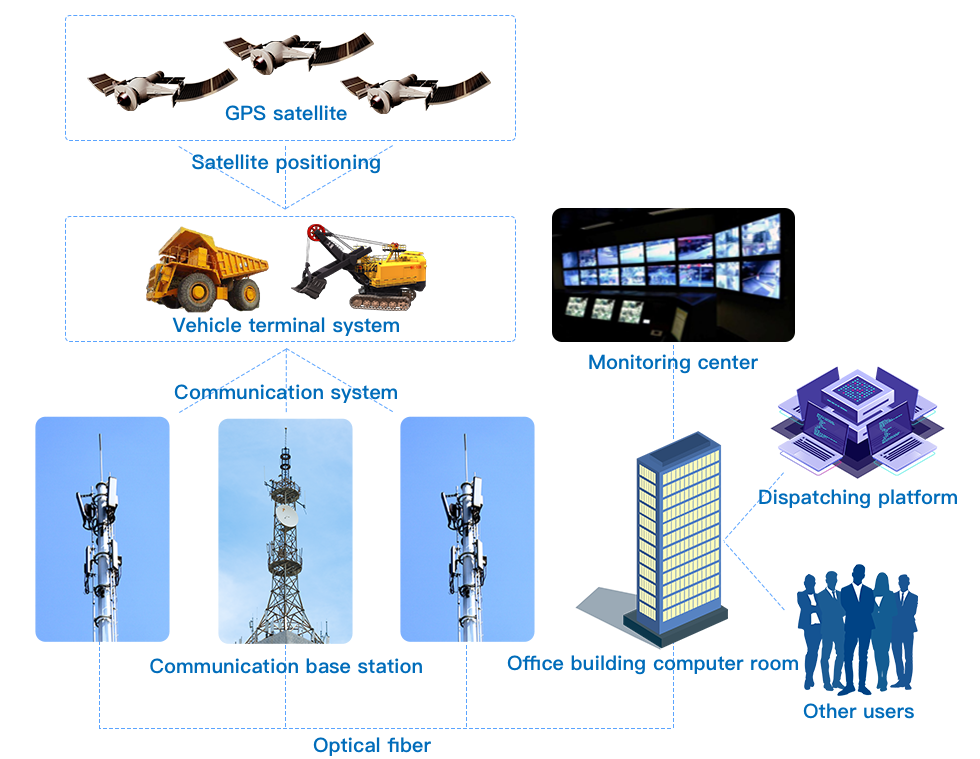

【Introduction of system】

The open-pit mine truck dispatching system is based on 3D visualization technology, GIS technology, GPS technology and so forth. Through the real-time collection, analysis and processing of production process data, the system establishes a detailed and accurate production process basic database, thus conducting the query statistics of the location, state, production, mileage and different times of equipment in a timely and accurate manner. The system can also view traffic density, equipment loading, equipment queuing and so forth, reflect the site information through chart and other visualized forms, and realize automatic measurement, driver evaluation and so forth, so as to improve the decision-making and management quality for the mine.

【Application value】

Increase production efficiency/improve management quality/raise reaction speed/reduce safety accident/reduce management cost.

1、Efficient dispatching

Through science-based and rational resource planning, the system ensures that there is no delay in truck operation and shovel operation, thus reducing fuel consumption and improving production efficiency.

2、Accurate control of grade

Through automatically adjusting the ore distributing strategy and optimizing dispatching, the system ensures that the grade target is reached, thus reducing the mining and beneficiation cost.

3、Operation monitoring

The system carries out comprehensive monitoring of system and equipment, quickly responds to operation anomaly, improves system stability, and guarantees operating efficiency.

4、Safety monitoring

The system achieves dangerous production area alert, equipment safety warning and visualized and centralized safety management and control.

5、Monitoring and maintenance of equipment condition

The system automatically collects the state and condition data of equipment, and carries out pre-diagnosis and treatment of equipment failure.

6、Prevention of management loopholes

The system can prevent not only cheating and slack work, but also such management loopholes as tandem shovel, oil theft and overspeed.

【Strengths of system】

1、High openness and integration ability.

2、While enriching the business function, the system significantly simplifies the terminal interface, thus making the vehicle terminal interface more friendly.

3、The system adopts the dispatching-centered design idea and intelligent business algorithm. Compared with the design of traditional system, the system simplifies the operation of the vehicle terminal, thus reducing the influence of human intervention on system accuracy.

4、The dispatching platform employs the pure B/S architecture. Both the subsidiary’s project site and the group headquarters can gain convenient access to the system via web page, thus avoiding the geographical restriction on access.

5、For communication, the system adopts the middle-ware technology that complies with the international standard. The system is more stable and easier to expand. At the same time, the access cost of third-party system is further reduced.

6、The system reserves the automatic driving interface. Moreover, the system provides standardized data acquisition and storage services, and gives a full consideration of the future development of the mine.

【Application case】

Henan Mengdian cement mine

The open-pit mine intelligent dispatching system has been successfully applied in a large number of domestic mines. Henan Mengdian project covers more than 80 mining trucks and excavators, and has a total area of over 3 square kilometers. The project adopts a 4G private network for network communication and data transmission. The system operates stably. The successful application of the intelligent dispatching system lays a solid foundation for Henan Mengdian to strengthen grade control, increase the utilization rate of mine resources, reduce the participation of personnel, especially drivers, enhance intelligent level, reduce production cost, and improve production efficiency.