【Summary of scheme】

With a long-lasting focus on the construction of digital and intelligent mine, Changsha Digital Mine has a integrated product system and a professional R&D team. With the wide application of large equipment for underground mine, a large number of enterprises need efficient dispatching of equipment. Based on many years of experience, the product developed by our company is our strength , the company has developed an integrated solution of underground mine intelligent dispatching system. This system has been successfully applied in the mines owned by Yunnan Copper Co., Ltd., Wisco Resources Group Corporation Limited and Zijin Mining etc.

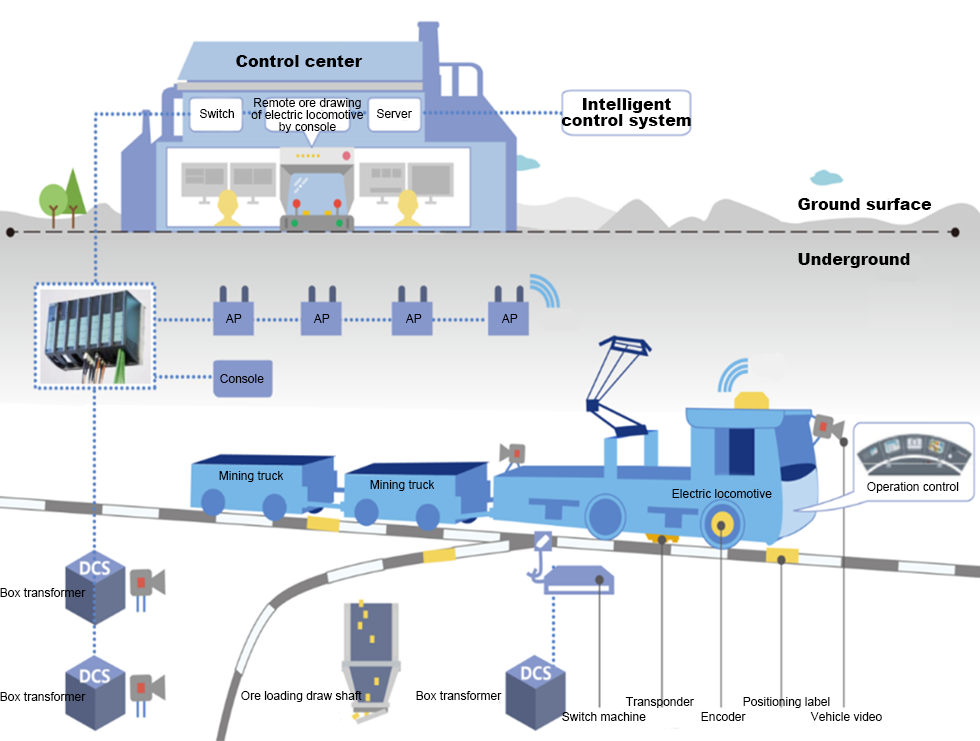

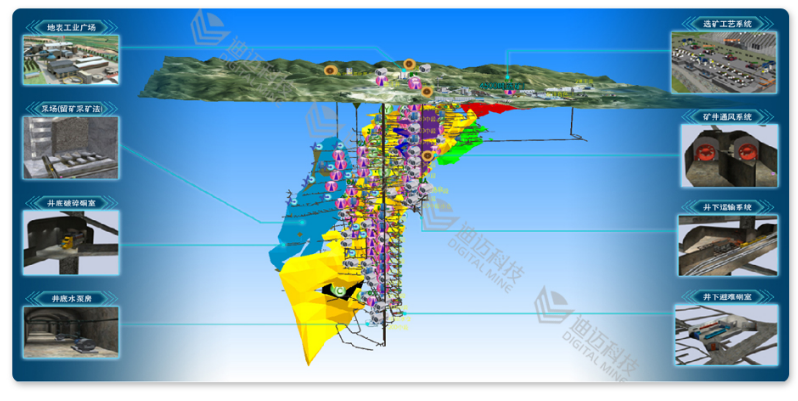

The underground mine intelligent dispatching system integrated solution combines “5G enterprise private network, production plan management, intelligent trackless equipment, driverless operation of electric locomotive, intelligent dispatching of equipment, regional security joint control, big data platform and control platform of 3D visualization management” into one. Setting the strategy planning target of “covering all the areas with one network, connecting all the businesses with one set of data, grasping all the information with one platform, operating all the equipment with one set of system”, the system comprehensively achieves the timely and comprehensive dispatching of mine work safety, reduces cost, increases efficiency, and improves corporate economic benefit.

【Application values】

1、Zero-distance interaction

Through introducing 5G, driverless operation and so forth, the system changes work environment to indoor control, thus achieving the remote, zero-distance interaction between man and machine.

2、Intelligent dispatching

Utilizing multiple factors and in conjunction with the comprehensive dispatching platform, the system achieves the intelligent dispatching of underground working face with production plan, production execution and production scope as the core.

3、Data mining

Utilizing multiple factors and in conjunction with the comprehensive dispatching platform, the system achieves the intelligent dispatching of underground working face with production plan, production execution and production scope as the core.

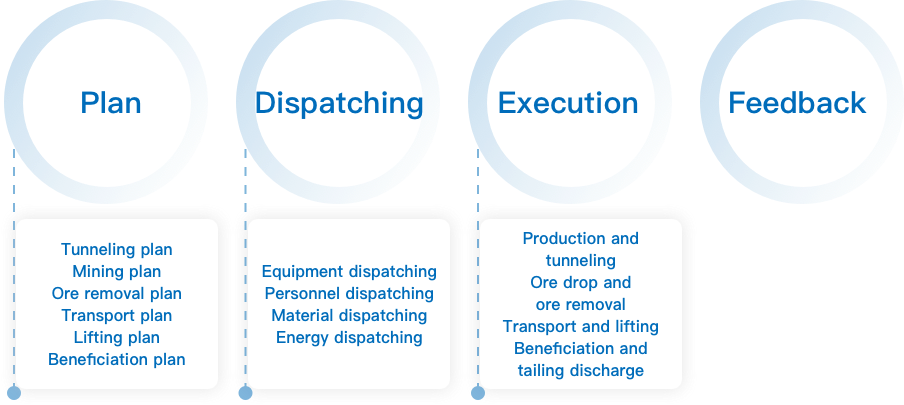

【Business process】

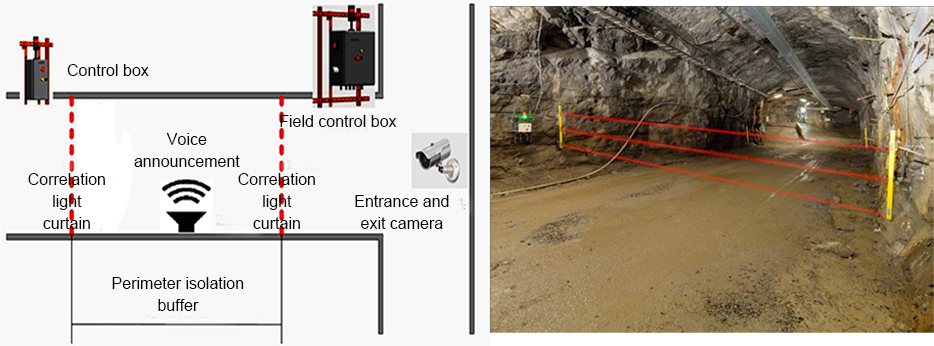

Based on 5G+IoT network, the system distributes the production plan data to equipment; the equipment carries out production through remote control, and the system conducts real-time monitoring and dispatching of production plan; the system establishes a draw shaft material level monitoring and regional security joint control system to guarantee production safety. The system realizes the timely and comprehensive dispatching of mine work safety. Through real-time online monitoring and simulation and reproduction of production process status, the system achieves the visualized and centralized management and control of mine work safety.

【Main functions】

1、5G enterprise network

2、Production plan management

3、Intelligent trackless equipment

4、Intelligent electric locomotive

5、Intelligent dispatching of production equipment

6、Regional security joint control

7、3D visualization management and control

8、Big data analysis

【Features of system】

1、Based on the 5G+IoT communication technology, the system solves the problem that it is difficult to carry out communication at the mine working face terminal. Moreover, the system guarantees real-time communication with equipment, thus achieving the timely dispatching of production.

2、Taking the production plan as the core, the system carries out whole-process, intelligent closed loop management of plan formulation, execution monitoring, feedback and analysis.

3、Through the remote control of equipment, the system improves the work environment for personnel, and reduces the underground operation of personnel, thus achieving the intrinsic safety of the mine; the system also reduces the underground operation process, effectively guarantees the working hours of personnel on duty, and improves the comprehensive work efficiency.

4、The system utilizes the big data technology to monitor and analyze the whole process of production dispatching, thus providing decision-making support for the comprehensive management of equipment, comprehensive dispatching of production and so forth.

【Classic case】

Comprehensive dispatching of scraper at Pulang Copper Mine

Pulang Copper Mine utilizes ore drawing system and ore removal index optimization technology to carry out multi-target ore drawing plan management under complex constraint conditions. It also formulates a detailed production, and improves the management target. Moreover, the mine transforms the scraper to achieve the intelligent operation of the scraper. The mine conducts real-time monitoring of production, mining and loading equipment and production at loading and unloading point, and carries out optimal dispatching management of production site.