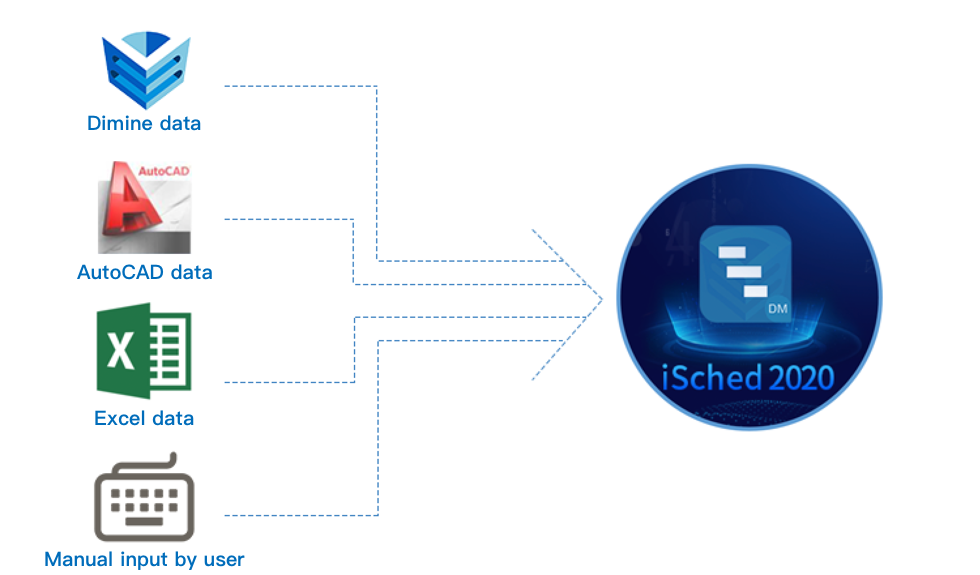

【Data preparation】

The system provides comprehensive data support, and supports the one-key data import of multiple mainstream software such as Dimine, AutoCAD, and Excel etc.

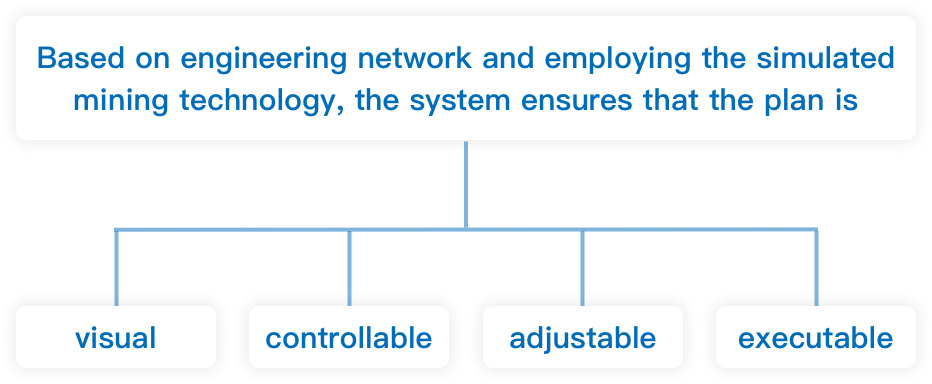

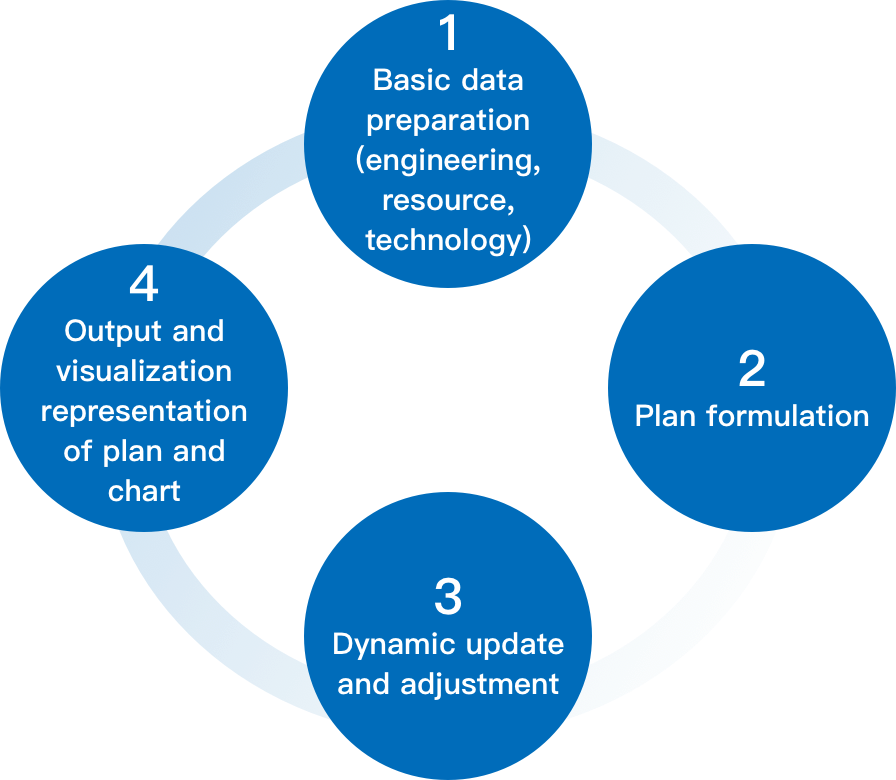

【Plan formulation】

1、Automation

According to basic data and constraint condition and in light of the existing resources of the mine, the system automatically prepares medium and long-term, short-term operation plans.

2、Multiple constraints

In the plan formulation process, through adding multiple constraints such as priority, equipment production capacity, process and spatial constraints, the system adapts the plan formulation to the reality of the mine, thus achieving the optimal mine production.

【Plan adjustment】

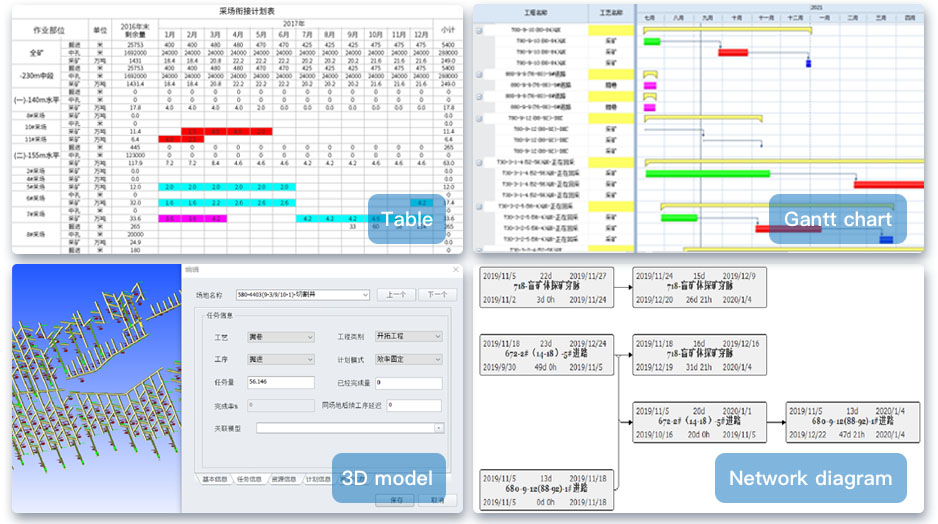

1、Four-point linkage

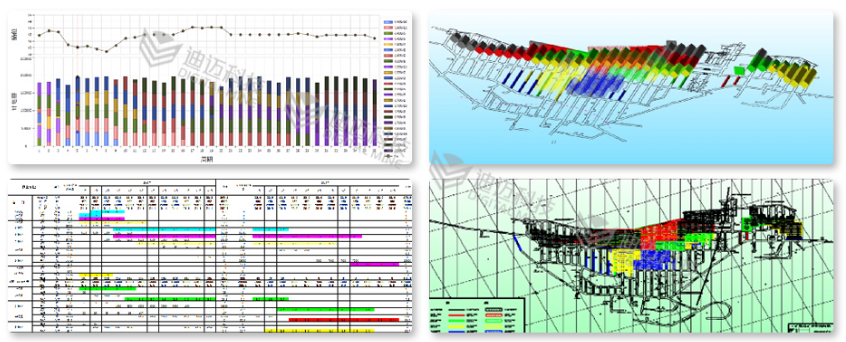

Based on multiple tools such as table, Gantt chart, 3D model and network diagram, the system completes the plan adjustment, thus achieving data interconnection.

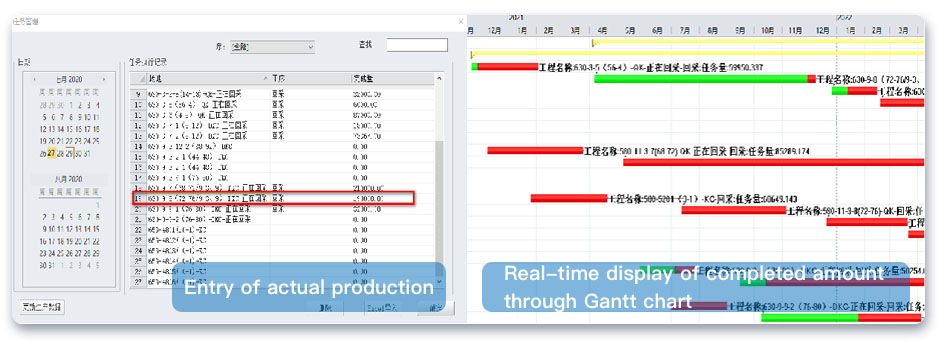

2、Real-time update of production

Based on Gantt chart, the system collects the real-time statistics of production data, so as to achieve the dynamic comparison of plan and production.

【Output of results】

1、Diverse presentation of results

The system can present the results of plan formulation in various ways such as Excel, animation, Gantt chart and histogram, and generates the production status of different periods.

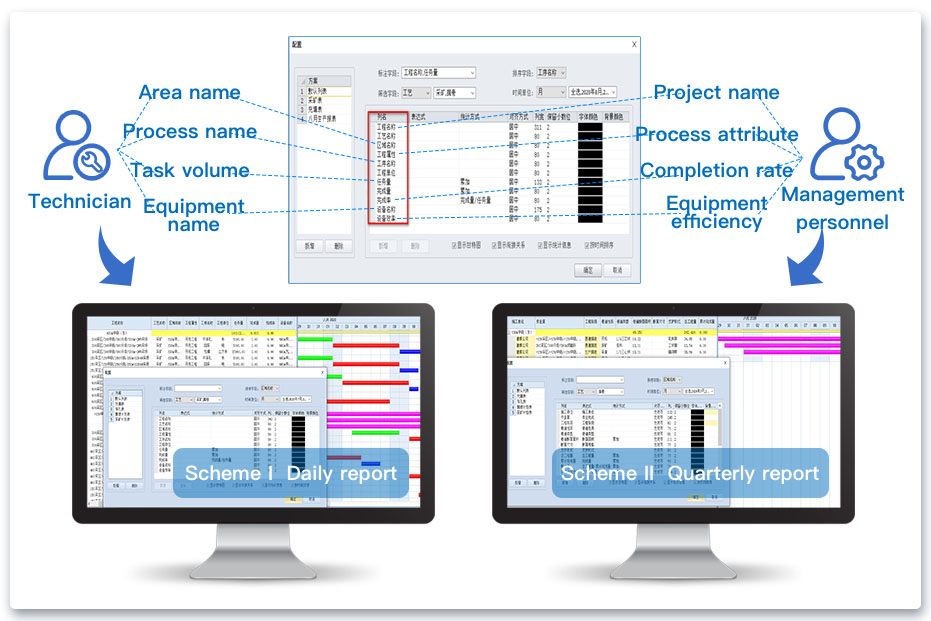

2、Customized output of report

The system provides various report templates for users to choose. The system can also customize various reports based on the user demand, so as to achieve the what-you-see-is-what-you-get-type report output mode.

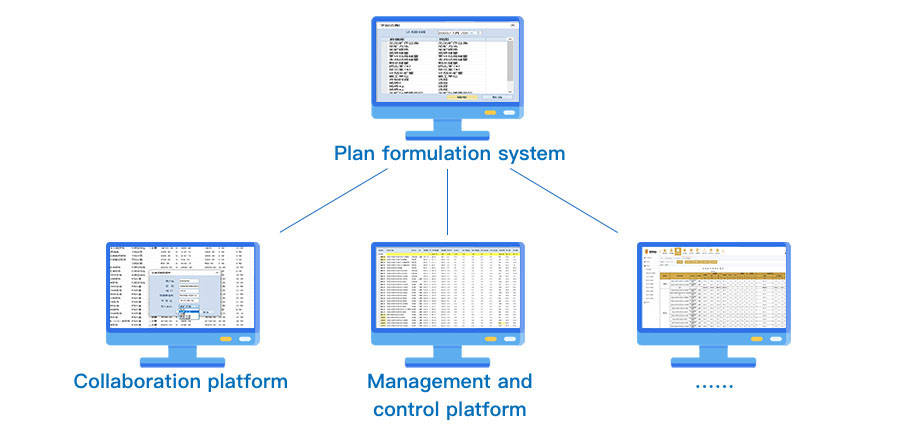

3、Plan distribution

The system can be flexibly connected to other systems to achieve data interconnection.

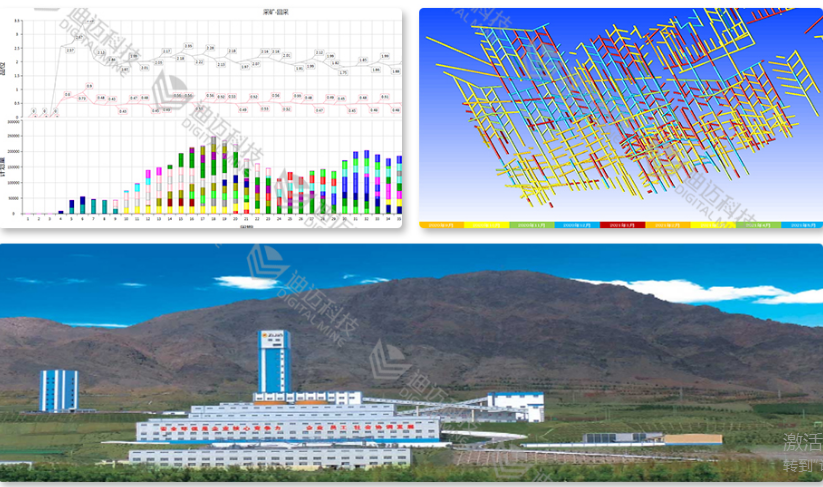

【Application cases】

1、Beiluo River iron mine

In conjunction with the mining technology through sublevel caving method without sill pillar of Beiluo River iron mine and on the premise of satisfying such constraint conditions as mining process sequence, stope mining sequence, orderly scheduling and reasonable distribution of equipment, production capacity limitation and retreat mining safety, the system sets the plan target of reaching the annual concentrate quantity of the mine, and utilizes the plan automatically prepared mathematical model based on target planning, to achieve the intelligent preparation of annual mining plan.

2、Urad Rear Banner Zijin mine

This mine carries out the simultaneous mining of multiple middle sections and multiple ores, with an annual production of 3.30 million ton. The mine employed the iSched plan formulation software to finish the preparation of three-year plan and achieve the one-key output of various reports. Compare to the traditional plan formulation mode, the software reduces the plan formulation personnel and working days from 15 and 8 to 30 and 10 respectively, thus greatly reducing the operating cost of plan formulation.